Ensuring Reliability with KSB Valves in High-Pressure Applications

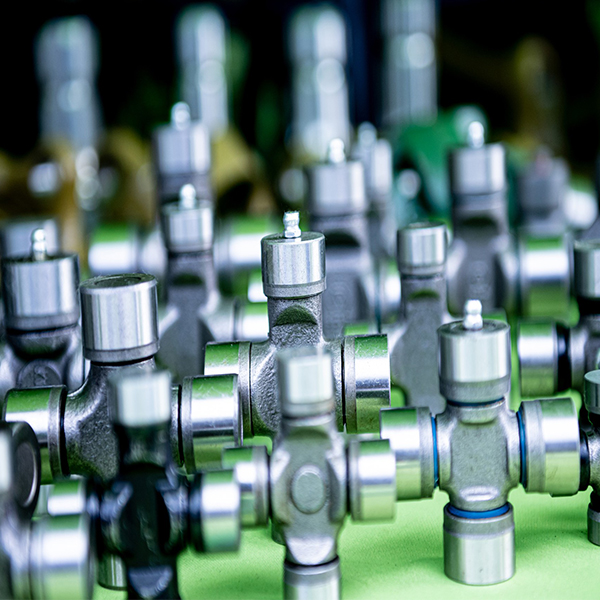

In industrial sectors such as oil and gas, power generation, and manufacturing, high-pressure systems are critical for maintaining the flow of fluids, gases, and steam throughout the facility. However, as with all sophisticated systems, high-pressure systems can encounter issues that jeopardize efficiency, safety, and operational continuity. One of the most crucial components for ensuring the performance and reliability of these systems are valves, which regulate pressure and flow rates.

KSB Pumps and Valves have been trusted for decades in industries that demand robust, reliable performance. These valves, designed to handle high pressures and extreme operating conditions, offer critical solutions to the challenges faced in high-pressure systems. In this article, we will delve into common issues faced by KSB valves in high-pressure systems, troubleshooting methods, and how the advanced features of KSB Pumps and Valves can prevent these problems.

Advanced Technology for Enhanced Performance

KSB Valves are engineered with industry-leading features to ensure long-term performance and reliability in high-pressure applications. Here are some of the key features that set them apart:

- Durability Under High Pressure

KSB valves are built to handle extreme pressures without compromising safety or performance. These valves are constructed from high-strength materials, designed to endure the stress of high-pressure environments, preventing failure even under the most demanding conditions.

- Precision Control and Flow Regulation

KSB valves are designed to provide precise flow control, which is critical in high-pressure systems where even small deviations in flow rates can lead to system inefficiencies or failures. Their highly accurate valve actuators ensure that pressure and flow rates are maintained with minimal fluctuation.

- Leak Prevention

A major concern in high-pressure systems is leakage, which can cause safety hazards and loss of efficiency. KSB valves feature advanced sealing technology, reducing the risk of leaks in systems that operate under extreme conditions.

- Corrosion and Wear Resistance

The materials used in KSB valves are highly resistant to corrosion and wear, extending the lifespan of the valves and minimizing the need for frequent replacements or maintenance.

KSB Valves in High-Pressure Systems

KSB valves are used in a wide range of industrial applications where high-pressure systems are integral to the process. Below are a few key industries that benefit from the advanced technology of KSB valves:

- Oil and Gas

In the oil and gas industry, high-pressure pipelines and refining processes require valves that can handle high fluid pressures while maintaining safety and efficiency. KSB valves regulate the flow of oil, gas, and chemicals safely through pipelines, production facilities, and refineries.

- Power Generation

High-pressure steam systems in power plants depend on reliable valve performance to regulate steam flow and pressure. KSB valves are used extensively in boiler feedwater systems, steam turbines, and condensate systems to ensure that high-pressure steam is safely and efficiently managed.

- Chemical Processing

In chemical plants, where high-pressure reactors are common, valves must operate under extreme conditions. KSB valves are critical for controlling the flow of chemicals in and out of reactors, ensuring that production processes run smoothly and safely.

- Water Treatment

In municipal and industrial water treatment facilities, KSB valves manage high-pressure water systems used for filtration, pumping, and distribution. The long-lasting durability and precise flow control of KSB valves ensure that these systems maintain high efficiency.

Troubleshooting Common Issues with KSB Valves in High-Pressure Systems

Even with the advanced engineering behind KSB valves, certain issues can arise in high-pressure systems that require troubleshooting and maintenance. Let’s take a look at some of the most common issues and how to address them.

- Valve Leakage

Leakage is one of the most frequent issues in high-pressure systems. While KSB valves are engineered to minimize leaks, they can still occur due to worn seals, improper installation, or system pressure spikes. If you notice leakage around the valve seat or actuator:

- Solution: Inspect the seals for wear or damage, and replace them if necessary. Ensure that the valve has been correctly installed, following the manufacturer’s guidelines. If the leakage persists, it could indicate an issue with system pressure, in which case, the pressure should be checked and adjusted accordingly.

- Sticking or Jamming of Valves

In high-pressure systems, valves can become stuck or jammed due to contaminants, corrosion, or sediment buildup, particularly in aggressive fluid environments.

- Solution: Regular maintenance and cleaning of the valve components can prevent buildup that leads to jamming. If contamination is suspected, install filters or strain relief valves to capture debris before it enters the valve. Additionally, check for proper lubrication, as dry components can lead to sticking.

- Erratic Flow Control

Erratic valve operation can occur due to improper actuator settings, mechanical failure, or system instability. This can result in fluctuating pressure or inconsistent flow, which compromises system efficiency.

- Solution: Calibrate the actuator settings to ensure they match the required operational parameters. Inspect the actuator for any signs of wear or malfunction, and replace if necessary. Regular system diagnostics can also help identify sources of instability and provide insights into improving control.

- Excessive Wear and Tear

In high-pressure systems, valves may experience increased wear and tear due to prolonged exposure to high-stress conditions, including erosion, cavitation, or thermal cycling.

- Solution: Implement periodic maintenance checks to detect signs of wear early. Replacing worn-out components such as seals, seats, and discs in time will help prevent more severe damage. Additionally, ensure the system is not operating above the recommended pressure levels to reduce unnecessary stress on the valve.

Why Choose KSB Pumps and Valves

When it comes to high-pressure systems, KSB Pumps and Valves are widely recognized for their reliability and advanced technology. Here’s why they stand out:

- Superior Quality and Durability

KSB valves are built to last, made with high-performance materials that resist wear, corrosion, and pressure-induced damage. This superior durability ensures minimal downtime and lower maintenance costs.

- Advanced Technology for Enhanced Efficiency

KSB valves incorporate state-of-the-art actuator systems and sealing technologies that provide precise flow control while minimizing leaks and reducing energy consumption. This improves overall system efficiency and operational costs.

- Customizable Solutions

KSB offers customizable solutions tailored to the specific requirements of high-pressure applications. Whether it’s special materials, sizes, or configurations, KSB can provide the right solution to meet your operational needs.

- Proven Track Record

With decades of experience and global recognition, KSB’s reliable performance in high-pressure applications ensures peace of mind for industries that cannot afford downtime or failures.

Optimize Your High-Pressure Systems with KSB Valves

In high-pressure systems, the performance of valves plays a crucial role in ensuring efficiency, safety, and longevity. With KSB Pumps and Valves, industries can mitigate common operational issues such as leaks, wear, and erratic flow control, optimizing system performance and reducing costs.

Need a reliable valve solution for your high-pressure system?

Explore the full range of KSB Pumps and Valves available at Nanjing XYC. Contact us today for a quote or to learn more about how KSB valves can enhance your industrial operations.

Request a quote or browse our full range of industrial solutions on the Nanjing XYC website.